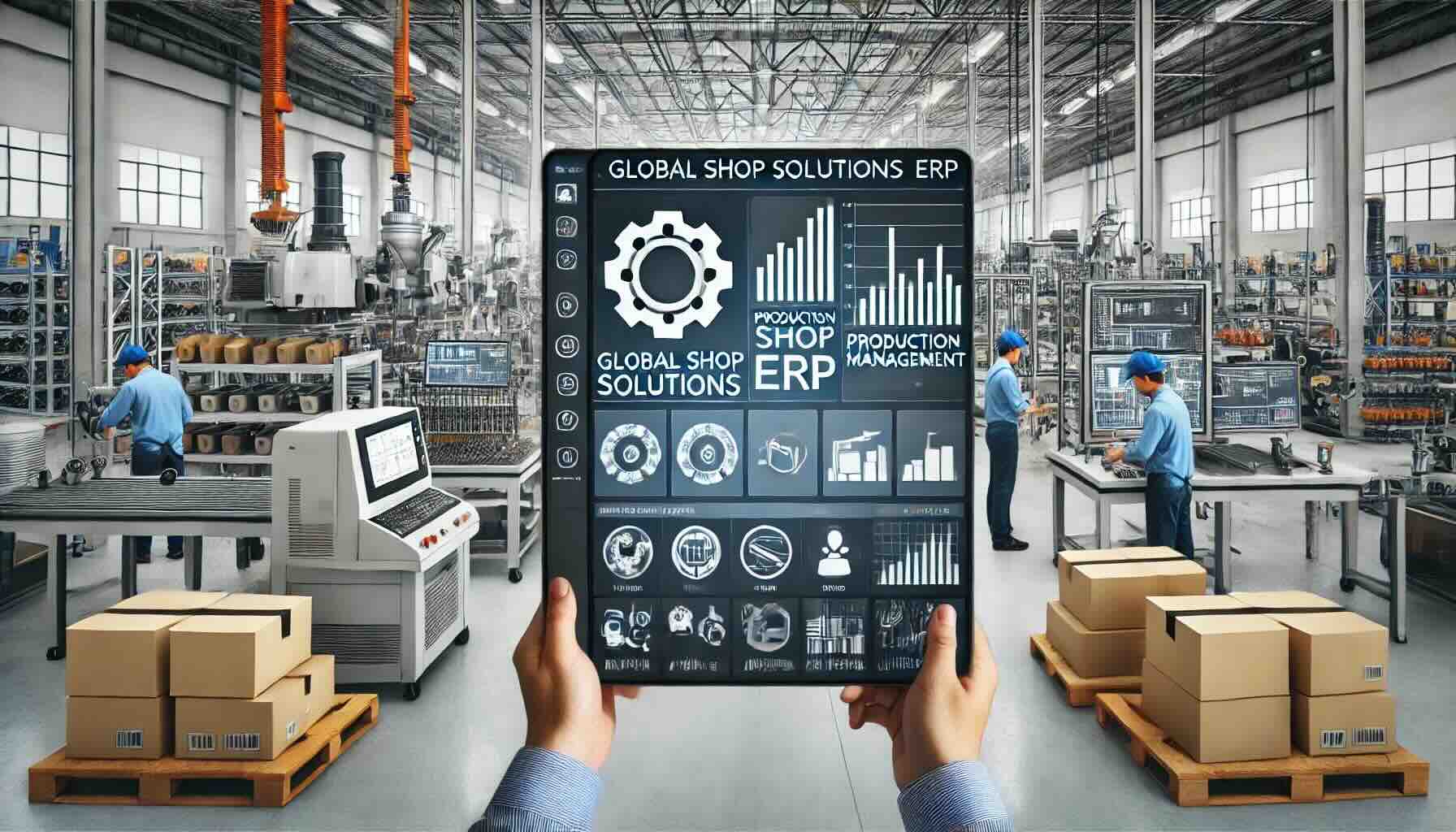

Is Global Shop Solutions a Good ERP for Manufacturing?

In the manufacturing industry, operational efficiency, accurate inventory management, and streamlined production processes are crucial for maintaining competitiveness and profitability. Enterprise Resource Planning (ERP) systems are designed to integrate various business functions, enhancing overall efficiency and productivity. One such ERP solution is Global Shop Solutions. But is Global Shop Solutions a good ERP for manufacturing? This blog will explore the strengths and weaknesses of Global Shop Solutions, helping you determine if it is the right fit for your manufacturing operations.

Strengths of Global Shop Solutions for Manufacturing

- Comprehensive Functionality Global Shop Solutions offers a wide range of modules tailored specifically for the manufacturing industry. These include production planning, inventory management, quality control, and supply chain management. This comprehensive functionality ensures that all aspects of the manufacturing process are covered, from procurement to production to distribution.

- User-Friendly Interface One of the key strengths of Global Shop Solutions is its user-friendly interface. The intuitive design makes it easy for employees at all levels to learn and use the system effectively. This ease of use reduces the learning curve and helps improve productivity quickly.

- Real-Time Data and Analytics Global Shop Solutions provides real-time data and analytics capabilities, allowing manufacturers to monitor production processes, inventory levels, and supply chain activities in real-time. This real-time visibility enables quick decision-making and enhances responsiveness to market demands and production issues.

- Customization and Flexibility The platform is highly customizable, allowing manufacturers to tailor the system to their specific needs. This flexibility ensures that Global Shop Solutions can adapt to various manufacturing processes and workflows, providing a personalized solution that meets the unique requirements of each business.

- Strong Support and Training Global Shop Solutions offers robust support and training options for its users. The company provides comprehensive training programs and ongoing support to ensure that users can maximize the benefits of the system. This strong support structure helps minimize downtime and resolve issues quickly.

Weaknesses of Global Shop Solutions for Manufacturing

- High Implementation Costs One of the primary drawbacks of Global Shop Solutions is its high implementation cost. The initial setup, customization, and integration fees can be significant, which may be a barrier for smaller manufacturing businesses with limited budgets. Ongoing maintenance and support costs can also add up over time.

- Complex Implementation Process Implementing Global Shop Solutions can be complex and time-consuming, particularly for larger manufacturers with extensive existing systems. The transition to a new ERP system requires careful planning, significant resources, and potentially, the assistance of external consultants. This complexity can delay the realization of benefits.

- Customization Challenges While Global Shop Solutions offers a high degree of flexibility, extensive customization may require additional time and financial investment. Businesses with specific and complex needs might incur higher costs to tailor the system to their exact requirements. Custom development and integration with other systems can also be resource-intensive.

- Scalability Concerns Although Global Shop Solutions is suitable for small to mid-sized manufacturers, very large enterprises with extensive operations might face scalability issues. As the business grows, the system might require additional resources and upgrades to handle increased data volumes and user numbers effectively.

Conclusion

Global Shop Solutions offers a range of powerful tools that can significantly benefit manufacturing businesses. Its strengths in comprehensive functionality, user-friendly interface, real-time data and analytics, customization, and strong support make it an attractive option for many firms in this sector. However, the system also presents challenges, such as high implementation costs, complex implementation processes, customization challenges, and potential scalability concerns. Manufacturing businesses must weigh these factors carefully against their specific needs and resources.

Ultimately, whether Global Shop Solutions is the right choice for a manufacturing business depends on its size, budget, and operational requirements. By thoroughly evaluating these aspects and considering potential challenges, manufacturers can make an informed decision that aligns with their strategic goals and enhances their operational efficiency.

Click this link to find out more about Global Shop Solutions.

To compare Global Shop Solutions with 100s of other ERP solutions, you can use our new AI-powered Compare ERP tool. It’s free to use and you get a guaranteed discount on your first year’s licence fees with a referral from Compare ERP.