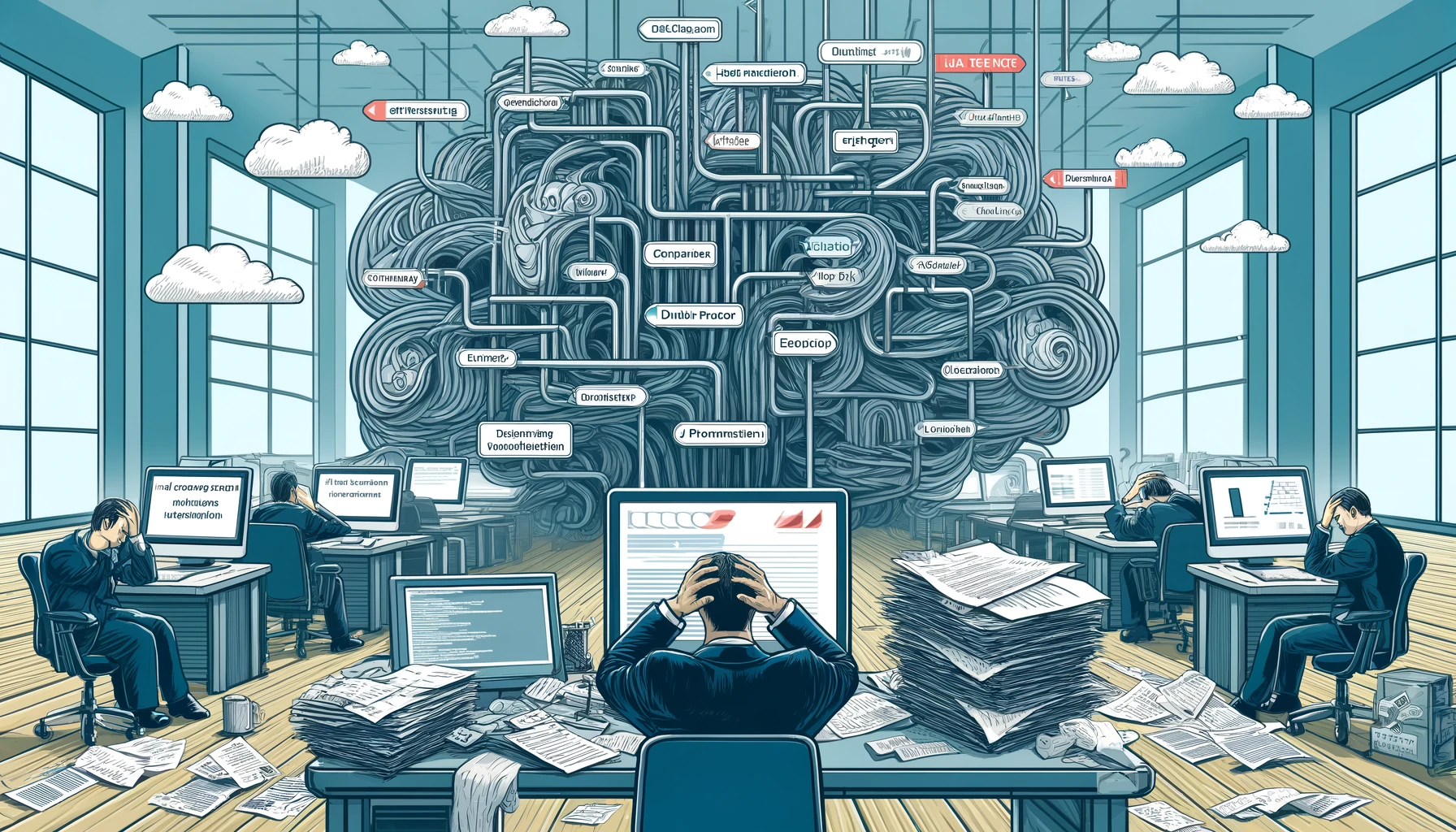

Top 10 ERP Mistakes to Avoid When Implementing a New System

Implementing an Enterprise Resource Planning (ERP) system is a significant investment in time, resources, and finances for any organization. While the right ERP system can streamline operations, enhance efficiency, and drive growth, mistakes in its implementation can lead to costly setbacks and operational disruptions. Drawing from industry experiences and expert insights, this blog outlines the top 10 ERP mistakes organizations often make when implementing ERP systems and offers guidance on how to avoid these pitfalls.

1. Inadequate Requirements Analysis

Failing to conduct a comprehensive analysis of business requirements is a fundamental error. Without understanding specific needs, the chosen ERP may not align with business processes, leading to inadequate solutions and potential system underutilization.

2. Insufficient Stakeholder Involvement

Excluding key stakeholders in the decision-making process can result in a lack of buy-in and resistance to change. Involving a diverse group from the outset ensures that the system meets various departmental needs and gains broad support.

3. Underestimating the Total Cost of Ownership

Many organizations overlook indirect costs such as training, maintenance, and future upgrades. Accurately estimating the total cost of ownership helps in making informed budgetary decisions and avoiding unexpected expenses.

4. Over-Customization

While customization can tailor an ERP to specific needs, excessive modifications can complicate the system, increase costs, and complicate future updates. Striking a balance between customization and out-of-the-box functionality is crucial.

5. Neglecting Change Management

Underestimating the human element of ERP implementation is a common mistake. Effective change management, including training and communication, is essential for smooth transition and user acceptance.

6. Poor Vendor Selection

Choosing an ERP vendor based solely on cost or brand name, without considering support, compatibility with existing systems, and industry expertise, can lead to unsatisfactory results. Thorough vendor evaluation is critical.

7. Inadequate Testing

Skipping or rushing through the testing phase can lead to undetected issues surfacing post-implementation. Comprehensive testing is necessary to ensure the system works as intended and meets all requirements.

8. Not Planning for Data Migration and Integration

Failing to plan for the complexities of data migration and system integration can cause data loss and operational disruptions. A well-structured data migration and integration strategy is vital.

9. Ignoring Scalability and Future Growth

Implementing an ERP system that does not scale with business growth can render it obsolete in a short period. Future-proofing the system for scalability and adaptability is essential.

10. Neglecting Ongoing Support and Training

Post-implementation, continuous support and training are crucial for dealing with issues and adapting to system updates. Regular training ensures users remain proficient and the system maintains its effectiveness.

In conclusion, successful ERP implementation requires thorough planning, stakeholder involvement, and an understanding of the organization’s unique needs. By being aware of these top 10 ERP mistakes and proactively addressing them, organizations can significantly increase their chances of a successful ERP implementation, ultimately leading to improved efficiency, reduced costs, and enhanced business processes.

The Compare ERP AI Comparison Engine uses artificial intelligence and machine learning to map your unique requirements to more than 100 ERP solutions. It’s free to use and you get a guaranteed discount on your first year’s fees when you get referred by Compare ERP.